A few years ago, I had the opportunity and privilege to design and build a high performance all-electric home in northwest lower Michigan. Read on to learn about the electric equipment, our experiences to date, and some data on hot water, minisplit, and overall energy use.

One of my primary motivations for prioritizing all-electric was to reduce reliance on fossil fuels and address not only direct concerns like combustion safety and indoor air quality, but also the higher-level issues of fossil fuel combustion, mining, and transport. In forgoing gas appliances and equipment in my home I am effectively shifting some of that fossil fuel use to the grid (our utility energy mix is currently 19% renewable). However, implementing energy efficiency measures and greening the grid should happen in parallel—we don’t have to wait for one before doing the other.

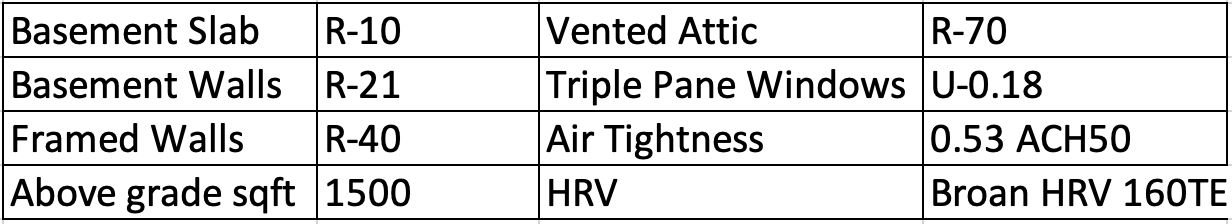

What does it mean to go high performance and all-electric in a cold climate? When focusing on the energy aspects of high performance, I like to think of it as first reducing the energy demand of the home, then meeting it as efficiently as possible. The former is driven by the building envelope and translates to using exterior continuous insulation, better windows, improved air tightness, and heat recovery ventilation as shown by the specs for my home:

The latter boils down to selecting high performance electric equipment—let’s take a look at that for HVAC, domestic hot water, and cooking.

HVAC

For heating and air conditioning, I installed two single-zone Fujitsu Halcyon cold climate mini-split heat pump systems (AOU12RLS3Y & AOU12RLS3H). Each system has an outdoor compressor paired with a wall-mounted indoor unit, and I could have instead selected a ducted or recessed ceiling unit if we had preferred hiding them. Additionally, it’s possible to “hide” wall hung units within the room by integrating them with built-ins or other features.

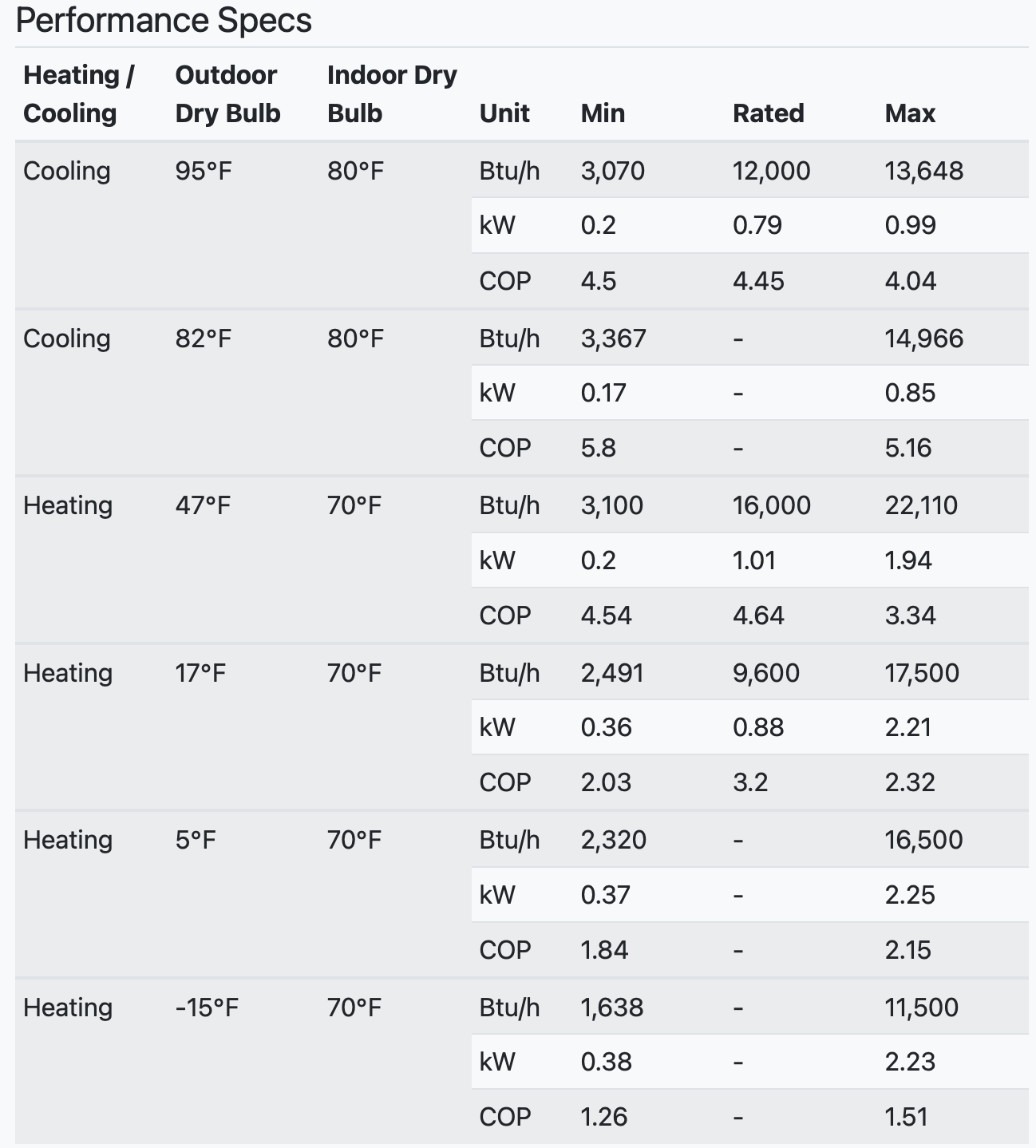

Heat pumps effectively harvest energy from the outdoor air to heat and cool the indoor space and allow for very high efficiencies that vary with outdoor temperature. The performance values for my units are 464% at 47ºF and 320% at 17ºF, and they maintain significant capacity down to -15ºF. It is important to note that these are rated efficiencies under laboratory conditions: real-world mileage will vary. In contrast, the output from gas or electric equipment is consistent regardless of temperature and efficiency is limited to 95-100%.

For a quick aside, I promise we are not breaking the laws of thermodynamics with those efficiencies, instead it’s a different definition of efficiency. The fundamental definition of efficiency is energy out divided by energy in. In this case though, we are only interested in the input energy that we must pay for, i.e. the electricity, and we ignore all the free energy harvested from the air. Another way of looking at it is for every one unit of energy I pay for, I am getting 3.2 units out at 17F. At 17F, instead of my electricity for heating costing $0.12/kWh, it comes in at $0.038/kWh. If I were using electric baseboard which is essentially 100% efficient, I would effectively be paying the full $0.12/kWh for heating energy. In several areas, electric heating with heat pumps beats propane on an energy output basis but still has a bit to go to compete with natural gas.

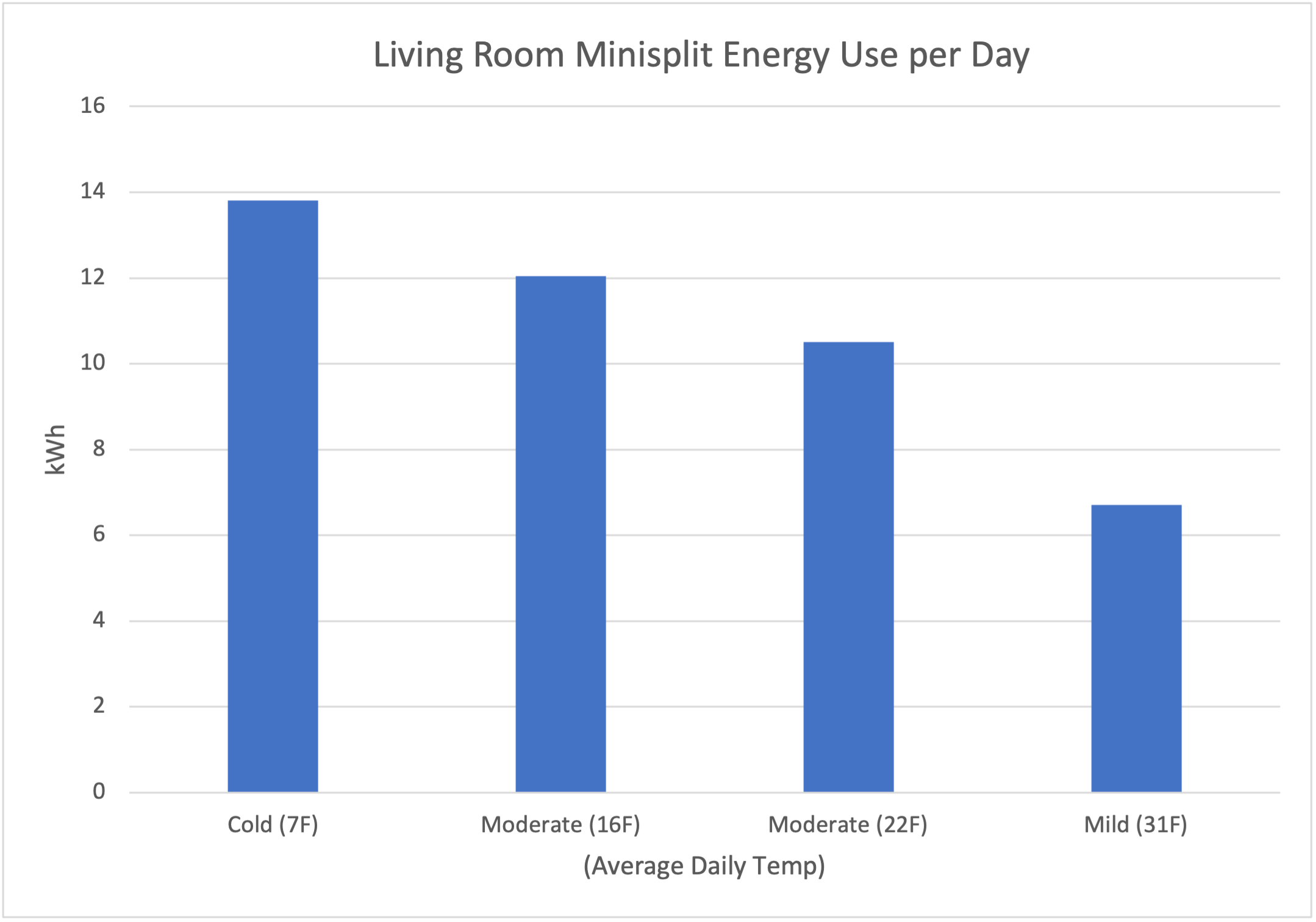

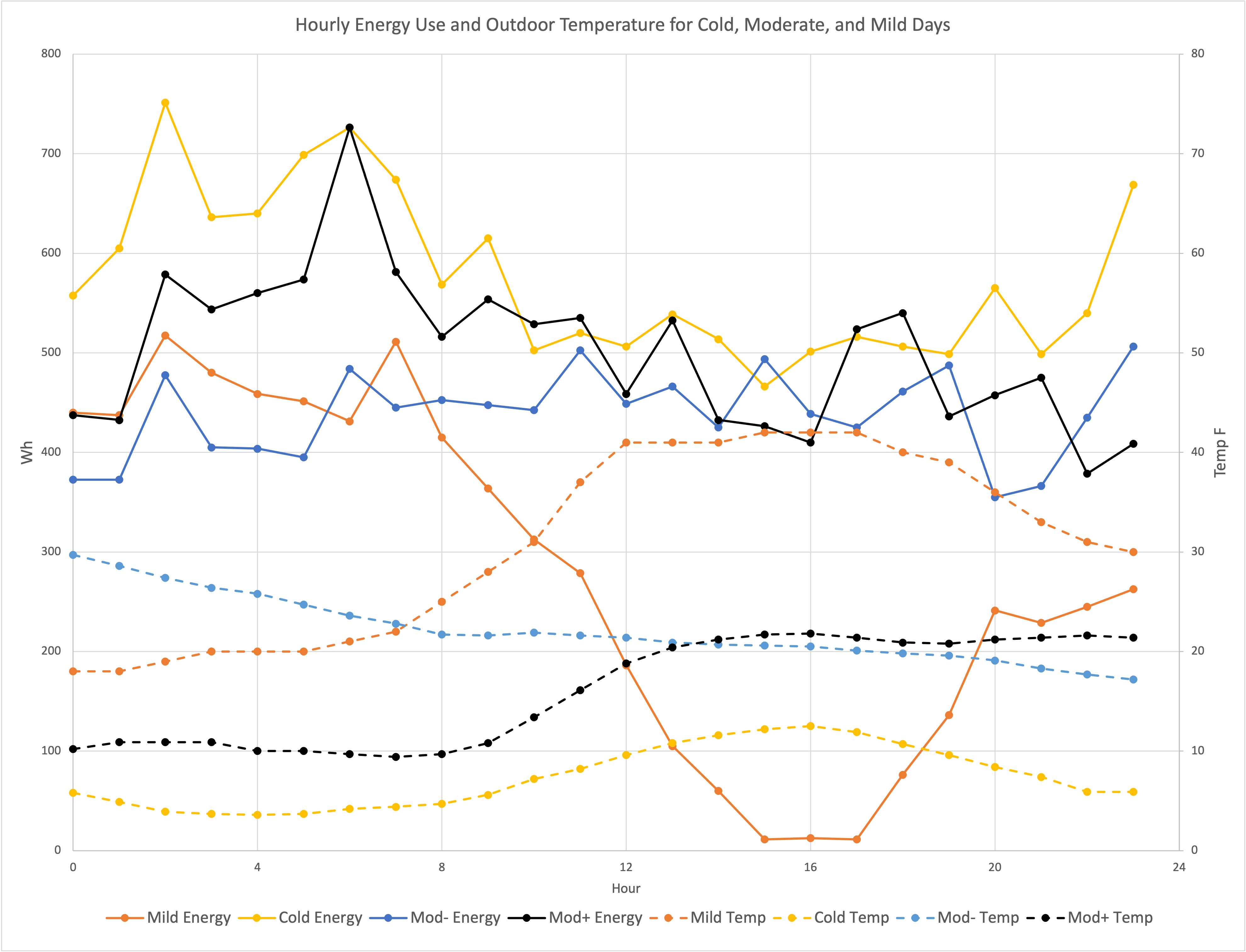

We are emerging from our third winter with this heating system. In short, the systems have been great and functioned as they were supposed to. About a month ago, temperatures dipped below 0 and hung out in the single digits for a few days. The house stayed warm and comfortable. I installed an energy meter on one of the systems to get a better idea of what our energy use looked like under various conditions. In the charts below we can see hourly energy use vs temperature and the total energy use per day for a cold day, two moderate days (one where is warming up throughout the day [mod+] and one where it’s cooling down [mod-]), and a mild day. We can expect a reasonable correlation of energy use vs temperature, but other factors, particularly solar gain (how sunny it was), can have quite an impact as well.

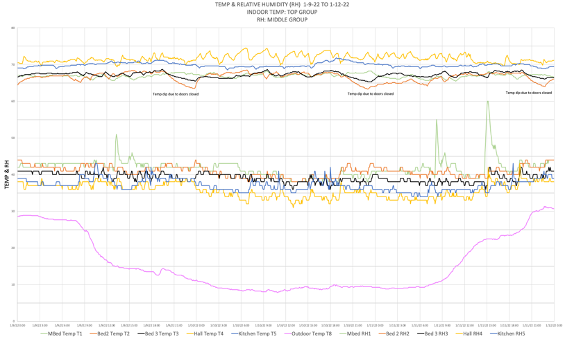

Being an energy nerd and experimentalist, I was willing to push the envelope quite a bit with the minisplit system. Instead of running a ducted system to provide conditioned air to the three bedrooms and two bathrooms, I installed a single wall hung unit in the hallway. I knew going in that if the doors were closed the temperatures would dip in the rooms, which did indeed turn out to be true. I eventually installed some temperature data loggers to quantify the effect. The data shows that if the doors are open even slightly, the rooms are a few degrees cooler than the hallway. If doors are closed, the temperature difference increases to about six degrees. Once the doors are open again, the rooms recover reasonably quickly. This strategy works well for my family because we don’t spend any extended periods of time in our bedrooms with the doors closed.

Importantly, I want to stress that this strategy is one of several options and can work if it meets your or your client’s requirements. For example, if they say “we keep our doors closed all day or when we’re sleeping”, this is not going to be a good approach. In such a case, a ducted system that delivers conditioned air directly to each space would be more appropriate.

Hot Water

We started off with a standard electric resistance water heater. After researching heat pump water heaters (HPWHs) a bit more, I regret not starting out with a HPWH as it showed a potential of using two-thirds less energy. I ended up installing a 50 gallon unit (Richmond 10E50-HP4D) about a year after moving in. However, I managed to grab some performance data before the installation and was able to compare performance between the two. Before getting into that data and experience, I’ll provide some background on the HPWH.

In cold climates, the typical unitary or packaged HPWH needs to be placed indoors or in a buffered space like a garage to maximize efficiency. This allows the unit to operate in heat pump mode most of the time (the most common HPWH units are “hybrid”, meaning that a backup electric resistance element will kick in when needed). Like mini-splits, HPWHs capture energy from the air to heat the water: however, unitary systems rob heat from the space where they’re placed. This provides a cooling effect which is great during the summer, ok in the shoulder months, and not so great in the winter. In cold climates, units should ideally be in a basement where the winter cooling effects are more acceptable. If this is not possible, a location that is conditioned by a minisplit is the next best spot. They should not be fully or partially ducted to the outdoors in cold climates due to depressurization and make up air requirements. Also, HPWH performance reduces with ambient temperature and most units switch to resistance only mode around 40ºF.

A few other considerations relate to noise, sizing, and controls. They are noisier than their counterparts, and sound attenuation should be considered in the case they can’t be reasonably isolated. On sizing, generally the larger the better as this will extend the heat pump run time and be more efficient. Standby jacket losses from storing the larger volume of water are trivial and can be ignored. Some of these systems allow for controlling time of operation. For example, if noise or the cooling effect are a concern, this particular unit can be set to run overnight. When coupled with a large tank and potentially a higher setpoint, these strategies can allow for a single charge to last the entire day.

The HPWH I installed has four modes of operation:

• Heat pump: the unit will only operate in heat pump mode to heat the water. This results in longer run times and slower recovery and is the most efficient mode.

• Energy Saver: the unit will primarily operate in heat pump mode with limited use of the resistance elements. Recovery time will be slightly faster, with slightly increase energy use, compared to pure heat pump mode.

• High Demand: the unit will operate both the heat pump and the electric resistance elements to shorten recovery time and will increase energy use.

• Electric resistance: Heat pump is off and only resistance elements heat the water. This is the same as a standard electric resistance water heater and will result in highest energy use.

I started out in energy saver mode and found we were using about one-third the energy of the previous water heater, about 3.5 kWh/day vs 11 kWh/day on average. However, my family frequently ran out of hot water and we were not satisfied with the performance. I believe part of this was due to the hot water recirculation system (occupancy and temperature controlled) as the operator’s manual stated energy saver mode was not recommended with hot water recirculation.

After trying energy saver mode for a few weeks, I switched over to high demand mode and expected energy use to at least double. Much to my surprise, our hot water energy use increased by only 57% to an average of about 5.5 kWh/day and we have yet to unexpectedly run out of hot water!

Some closing thoughts on the HPWH: if I could do it over, I would increase the tank size from 50 to 80 gallons to maximize the heat pump operation. The unit is located in the unfinished and unconditioned side of the basement. The cooling effect minimally impacts us, and the noise is not an issue—we hear it when we are in the same room, but not throughout the house.

Cooking

When shifting from gas to electric for cooking, the two cooktop options are standard electric or magnetic induction (the only electric oven option is standard electric resistance). Induction systems use an electric coil below the stovetop surface to create a magnetic field. The magnetic field induces a small current within the highly resistive pan, which causes the pan to heat up. This process ends up being more efficient, responsive, and safer than its standard counterpart. Most of the energy is transferred directly to the pan, the magnetic field is highly controllable and rapidly responsive, and there is no direct heating of the stove surface—it will only get as hot as the pan. It is particularly nice not having extremely hot surfaces with two young children, one of whom likes to help cook.

We ended up selecting a GE PHS930SLSS induction range. My wife and I enjoy cooking, and we were dreading the shift from gas to induction. It ended up not being that big of deal. We burned some meals our first few times but quickly figured things out! We also had to sacrifice a few of our favorite pans; pots and pans must be magnetic to work (learn more about cookware compatibility here). We both prefer the aesthetic of a gas range. There is some buzzing and clicking with our appliance, particularly when using hybrid pans like ceramic pans with an induction compatible bottom. We like that there are 19 settings for the ‘burners’ that offer a high degree of control, the cooktop stays cleaner and cools down quickly after cooking, and water boils much more quickly. Ultimately, we can’t tell whether a meal was prepared on a gas or induction range, and we are satisfied.

Another factor for consideration was the indoor air quality (IAQ) concerns. At the time of design and construction, I was aware of a few studies on the impacts on IAQ from gas ranges, but admittedly it wasn’t a driving force in our decision. Recently, I’ve come across several other studies pointing to the detrimental effects on IAQ from gas ranges whether it’s from the small leaks in gas lines that develop over time or the combustion byproducts themselves and these further reinforce our choice of an induction range over gas.

Overall Energy Use

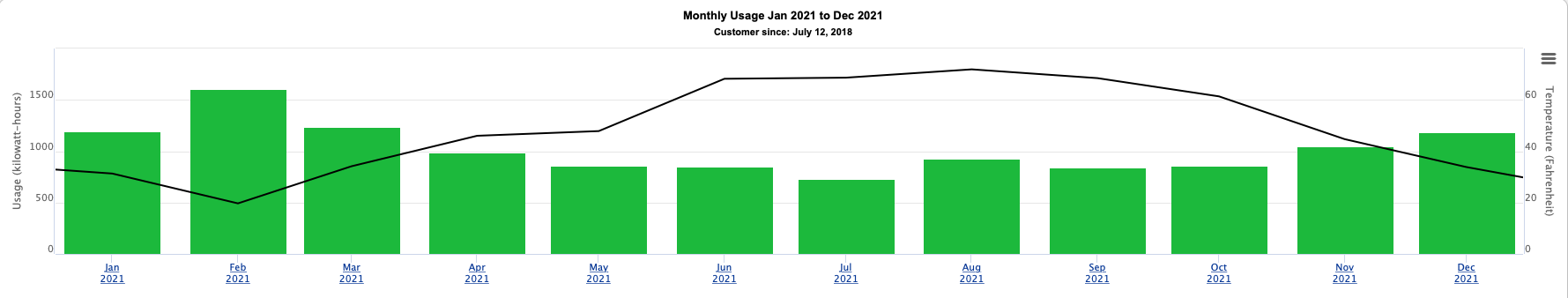

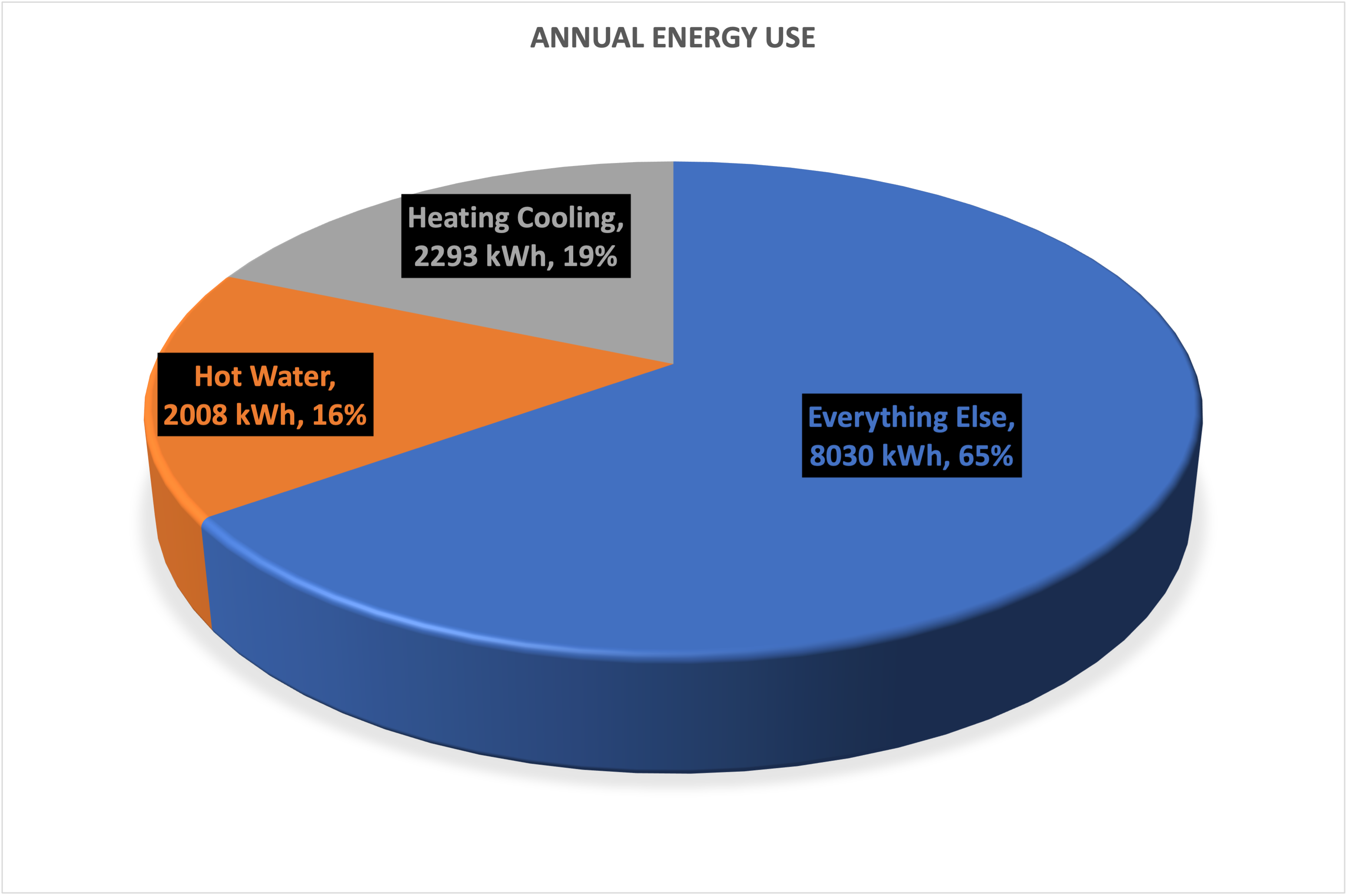

For the 2021 calendar year we used 12,330 kWh of electricity. The chart below from my utility company shows that we were fairly consistent with our month to month use from May-October. By picking a period in a shoulder month with a comfortable average temperature we can get a feel for the baseline energy used for a typical day. For the first week of September, we had an average temperature of 67, so it’s unlikely we had any heating or cooling, and our average daily energy use was about 24 kWh. If we subtract twice the daily energy use of the one minisplit (we have two single zone systems and can use one to approximate the energy use of the other) from the total daily energy use on those cold days above, we come in at about 20 kWh per day for our non-heating energy use. Let’s just take the average of the two, 22 kWh/day, and say that’s our baseline. And we can break this down even further because we know we’ve been using about 5.5 kWh/day for hot water. Then put it all together to get a rough estimate of how our annual energy use breaks out between heating and cooling, hot water, and everything else (appliances, plug loads, lighting etc.).

This analysis is showing about 20% of our annual energy use is for heating and cooling and 15% for hot water.

Final thoughts

We are approaching our fourth year in an all-electric home and don’t feel like we are missing out on anything without gas-fired equipment—the house is warm, the water is hot, and the food tastes great. Our energy use and associated costs have been low, even though we are using what is often the most expensive energy option. It’s made possible through the high-performance approach to design by first substantially reducing the loads through a thoughtful envelope design, then meeting those loads as efficiently as possible with heat pumps. At a grander scale, our design choices have prepared the house for a clean energy future. We can progress along with the grid or maybe leap ahead with a PV system; our utility offers a community solar panel purchase option as well. Ultimately, I can confidently say all-electric homes can work in cold climates. Contact us if you want us to help you get there, too!